Content Type MD [mark-down]

Capacitor Discharge M8 Machine

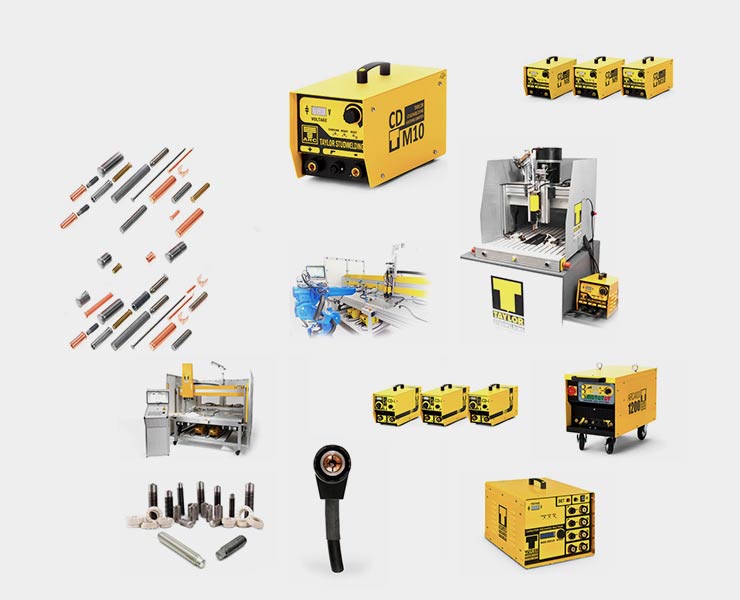

We are going to be showing you what is included when you purchase a Capacitor Discharge M8 (CDM8) equipment from us that Studfast. It would be coming in a box like this one.

First thing you might notice is you will have a Studfast CDM8 chart which will show you the settings, the recommended settings for each material state and each material sheet. It will tell you the voltage to use and the spring pressure to use, which is the only two things that you need to know that you need to sit on the machine before you start welding.

Included with every machine purchase, you get 5 for each of your choosing chucks. Some people call them collects, arbours or stud holder. So there's 3 and 4 and 5 and 6 and eight, which is all you need to begin stud welding.

Inside this bag contains a chuck and key. And this is the little tool that you'll use to unlock and lock your Chuck nut. The second type of kit needed is your double set of Earth clamps. You will also have the controller. Which is nice and light. I think the whole controller for one of these is 18 kilograms and yes, 18 kilograms, very portable. They now come with a longer power cord as well. So once you got once you got that all opened up, you plug in into the main supply.

Switch on the machine, then plug in your controller and tighten. Make sure cables are secure, don't do them too tight, but equally, don't make them too loose. If they're loose, they burn out and then you're into replacing both the controller and the socket.

We've got everything plugged in, what you want stud weld. Sheet that you're working from. So you see the front of the machine, so everything's checked. So from the five free chucks provided and using your chuck securing key that was included in the handtool package, give that a little looser off. Check inside. Tighten it back up. OK, not too tight, otherwise you can damage the internals on the hand tool. Yeah and switch the machine on. Depending on your stud material and your sheet material, refer to the Studfast contact setting sheet provided. Turn to the required voltage. And the spring pressure to the required spring pressure using the dial on the back goes from 1 to five.

OK, so we've checked the contact setting chart for the recommended setting. We've got 5 mil to studweld to stainless steel. So looking at the chart, we want 110 volts and spring pressure 2.5. So they're the only two bits of information that we need, so we're ready to work.

Now you have it.

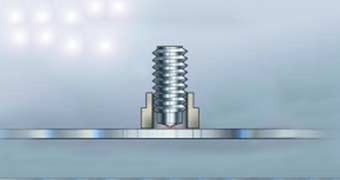

All he needs to do is reload the stud as you check the Chuck's backstop should be at the correct place. Now to give you one mil of clearance from the flange and the Chuck. And that's what we need to get started on the front of the handtool. We've got three legs, the three legs need to be in contact with the play to ensure that the stud is vertical. There are other accessories, such as a 30 millimeter nose cone, which assists when you're using templates for location.

When you are ordering a CDM8 equipment from ourselves, we can talk to you about, which would be better for your application. But if you let us know what you prefer out of the 30 mil nose cone or 22 mil nose cone.

We recommend the 30 millimeter nose cone. Alternatively, you've got tripod legs. And if you are welding studs of a little bit of a longer say, like 50 mil plus, we'd recommend we do some heavy duty 56 mil tripod legs. And if even longer than that, say around 100 mil, we do a special tripod leg assembly that's adjustable and you can weld as many studs as long as you like with that.

As mentioned before, when ordering a piece of equipment with us, you get 5 collects for each of your choosing. And if you let us know what studs you use and what diameter studs, we can include the right chucks for you.

Enquire by phone call or email us and enquire about the CMD8.

So everything you see here, apart from the studs, you get everything you see here. CDM8 is currently on offer at 1,300 pounds delivered to your door. So all of this to get started. All you need is some studs and inquire with either myself or Phil for prices on any sort of stuff that you use, whether that is ready to studs, pins, Earth tags, anything that you use for stud welding.

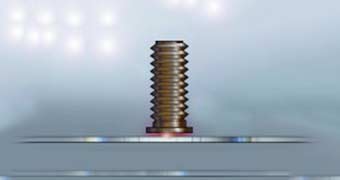

The CDM8 will weld up to and including 8 millimeter threaded CD weld studs. We've got such a wide customer base from many different industries, so we've got, you know, anyone that's working with sheet metal, anyone we're working with and close enclosures, metal enclosures that need earthing. We have got a quick example here of a PCB, so you can see that underneath the plastic spaces. We have got more steel studs welded in here, and that's how this PCB has been attached to this inside this metal enclosure. We've got a CD welded Earth tag here showing the Earth is in and out that's been CD welded so that you can do that with the CDM8 as shown here.

The possibilities are endless. Really, anyone working with any sort of sheet metal, we can show you how to weld on to it. The difference between the CDM8 and the CDi is the input voltages. The CDM8 can be set on either 240 or 110 volt. A lot of companies in the insulation business want it on 110 volt, so they may go for the CDI, which is a self voltage sensing machine. So if you've got 110 volt, just plug it into 110 volt and it will do the rest on its own. Whereas with the CDM range, you have to be specific. There needs to be alterations on the tapping on the transformer to make it into 110 volt.

Basically, the I's got an extra bit of technology in it called an inverter and it just automatically detects the voltage. OK right, if you're watching this video on YouTube. Don't forget to subscribe and visit our website, which is www.studfast-studwelding.com or call us on 01604 790901