Content Type MD [mark-down]

HELLO

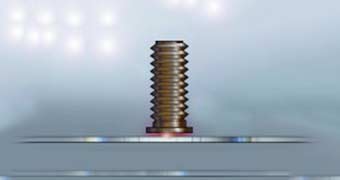

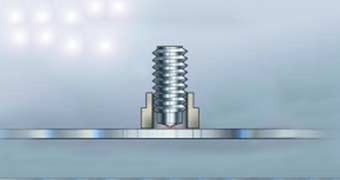

All right. OK so welcome to change your application method video. So what is studwelding? Why would somebody use it. Basically attach in a metal stud to a piece of sheet metal, stud weld process.

This is chosen when product appearance is critical, so fairly low energy is needed. There's not much burning, not much distortion, not much discolouration. So you can't really see that with weld or something on the other side. OK, so if people are looking for something that's fast, reliable and accurate, is that what stud welding is? That's basically it in a nutshell, describing stud welding itself. Yes OK. So why would studfast be considered for people to come to us and buy one of our machines. We should be considered because we see it as our problem. We see our customers problems as our problems because we know, we know it's a fairly niche subject in industry. And we've got a lot of experience in it. We hold what our customers need. So whatever type of stud they use, we've got a large range of stock of stainless steel, mild steel and aluminum studs ready to be shipped to our customers. The next day when they need them. And then any problems, any future projects that they want advice on. We're just more than happy to help with them, and then we can show them why. I said, well, this is right for the job and then and then they'll purchase them from us, and it's everyone's happy. Look studfast has been in business for over 35 years. Is that correct? That's correct. Yes, over 35 years.

what are the benefits then to studwelding.

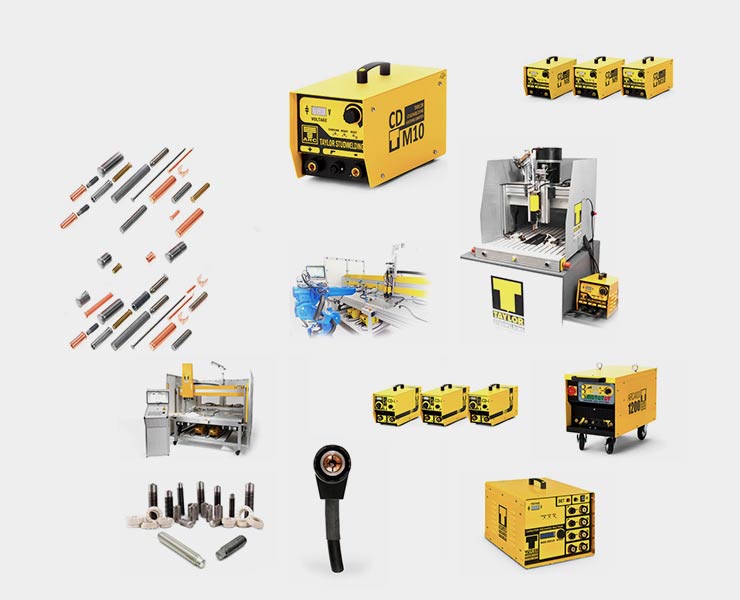

what are the benefits then to studwelding. The benefits are it's fast. It's basically, yes, a lot faster than the traditional methods welding two pieces of metal together. You don't require any finish in any shrouding gases. Very easy to use. So it's need minimal training on it and stud welding is portable. So like a standard stud welding machine like this weighs around 18 kilograms for the controller and the user can take it to wherever they're using it on site, in or just wherever their workspace needs to be. Is this a versatile process? Can it be applied to different types of materials? Yeah absolutely, Yeah. So I briefly touched on so the main three that we deal with are the stainless steel sheets, stainless steel studs, mild steel sheets, mostly of studs and aluminum sheets and studs. And then it's versatile in the way that there's numerous different methods and different attachments where you can, depending on your job and the size of where you need to put things. We will have the right attachment for you. So for example, you need to weld like right up against, say, in a steel enclosure. When you weld in, right up against the wall will have an attachment where you can just say you only need a few to get into the space and put that in, you know, especially the specialist chucks specialist extension assemblies that we can use. And yeah, very versatile in terms of weld into steel sheets. Who would this process apply to? So it applies to many industries and more and more are making themselves known. You know, all the time. But our main ones traditionally are anyone that works in sheet metal, sign makers, clading and insulation. So using our nail studs to hold in the insulation material a lot quicker than their previous methods, like drilling and tapping and just more conforming to like fire regulations and everything. So because you only access from one side. It doesn't make a hole in the structure. Mm-hmm Yeah. So our automotive industry, there's we're about roofing. Yeah, um, ventilation. Yep, Yeah. The food industry, food industry. And so not only food industry production lines with their machines have it ovens, ovens in your house, all have stood fixings in and that's how they were made. Um, grills, stove tops. Oh, what's the offer then? What are we currently running? So the offer that we're currently run in is a So our flagship machine, cdm8, we're currently offering a delivered machine, complete with everything you need to get started. So that's the controller, the hand tool and Earth needs, and also 5 chucks. And we're doing that delivered for 12 25 plus vat. We're doing that delivered the 12 25 plus vat. What's our guarantee with our product then? So what we say when we sell our machines instead is we tell all our customers that it's ours, that's our machine and it's our problem. So, you know, we're just happy to get them to their desired result, especially when they were. They're using our products. We're more than we just what we want to make it work. So you're confident that if they're using our machine and the studs that we offer, that will provide them with a good quality weld, very confident. Yep, we hear every day from our customers all the time. And yeah, very super confident about that. That's great, right? Then so call us today on our 01604790791 or put an inquiry through to [email protected]. Can you just confirm what type of material thickness is needed and can be done on very thin types of metals? And so the starting from 0.5 is what we'd be looking at, as a minimal material thickness. How long does it? Well so the weld can be completed in anything from one millisecond to 100 milliseconds. So very fast, very fast. What sort of process is does studwelding replace? OK, so there's six key areas studwelding replaces inserts. Inserts can work loose and studwelding makes your weld leakproof, and the weld formed is stronger than the parent material. Drilling and tapping is another area, so generally drilling and tapping is slow and withstood welding. It eliminates the need of penetration back welding again, a slow, messy and inaccurate process.

Conclusion

Studfast means you can weld straightaway, which is fast, accurate, reliable through bolting is another area stud welding replaces. Welding offers access from one side and again is more time efficient. Resistance Welding. You can take the machine to the area or the work surface. Machines are portable along with equipment and hand tools, and the machine and the final area is soldering, so there's no risk of erosion as stud welding Eradicates this.